Charcoal carbonization plant is is an plant used for do carbonizing work for wood ,fresh tree,coconut shell,sawdust briquette log,coal ,bamboo etc. Material ,make it them into charcoal without Smoke and Smell,safety charcoal for live use. Out company Anyang Ainuok as one of leading company offering charcoal production plant ,according client different requirement on various raw material.to offering the right machine .

Why Do Carbonizing Work?

Charcoal Production Furnace working is smokeless,no pollution

●Not only it has best carbonization effect and shortest carbonization time,

●It can collect wood tar oil and exhaust gas.

●After processed, this gas can used recycling fuel.

●Also it is no any open fire, totally dry distillation

●Temperature can be controlled and adjusted,highest can reach 800-1000℃

Where do we use Charcoal ?

●Charcoal in industry: It is mainly used in combining carbon of industrial materials,metallurgy, and the carburizing carbon of chemical industry.

●Charcoal in agriculture and animal husbandry: It can raise the soil temperature,maintain soil moisture, mitigate the organic fertilizers,improve soil PH.

●Charcoal in life: People often use charcoal heating, barbecue,as well as the fuel used to the tea and tobacco drying.

How is the quality of your products?Our products are manufactured strictly according to national and international standard,and we take a test on every grinder before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed

If products’ quality don’t accord to description as we give or the promise before you place order,we promise 100% refund.

Wood Charcoal Briquette Production Line

Wood Charcoal Briquette Production Line is an production plant convert waste wood,crop,biomass into wood briquette logs ,easy transport,and storage,and environment for nowadays. After carbonization

Introduction

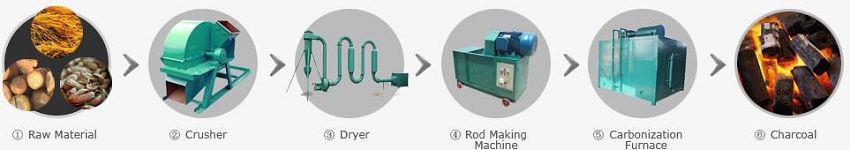

Production line : material→crusher →screw conveyor → Dryer→screw conveyor→Briquette machine→Carbonization stove → Briquette charcoal

Material

1.straw 2.sugarcane residue 3.coffee husk 4.cotton stalks 5.tobacco waste 6.mustard stalk 7.jute waste 8.bamboo dust 9.tea waste 10.wheat waste 11.palm husk 12.soybeans husk 13.rice husk 14.wood chips 15.agro waste |

The main parts of briquette Making Machine

●Forming of tube

Special casting steel, inner barrel boron treatment,continuously use for more than 5 months.

●Accessories

With a large factory of welding rod joint development of this special mechanism of carbon electrode welding process simple ,hardness up to more than 75 degrees ,and solved the crack resistance, don’t need preheat and weld directly.

●Propeller

Advanced design,high speed of producing rod ,high density,high resistance to wear,one welding time can work continuously for more than 30 hours.

Final Product

●Final shape:hexagon, pentagon, square, round

●Final length: 20-40 cm adjustable, according to per your needing

●Final size: Dia. 50mm, 60mm,70mm,80mm

Usage

●This Wood Briquette making Machine uses to make fuel briquette under high temperature and high pressure.

●Briquettes can be used in boiler, heating& warming. After carbonization, the briquette will become charcoal, used in BBQ.

Other Charcoal Making Machine

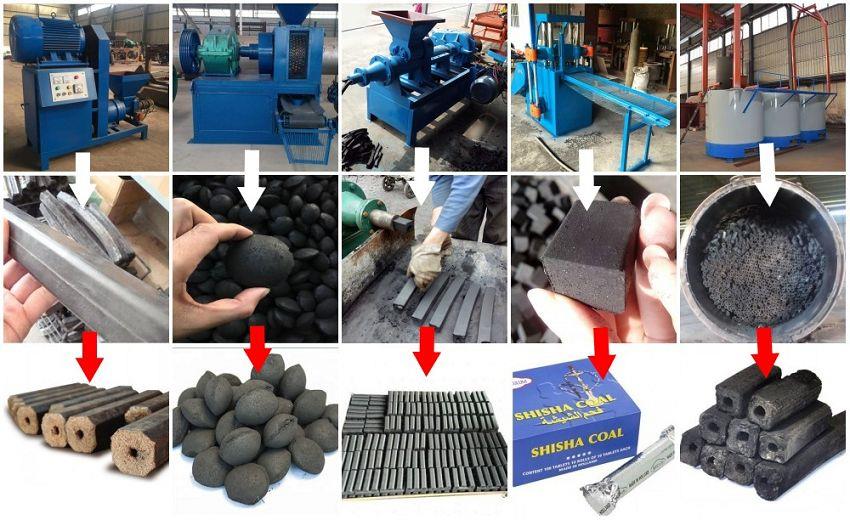

1.Briquette Making Machine

Screw press wood sawdust,rice husk into wood briquette,after carbonized into charcoal.

2.Coal Ball Briquette Machine

Hydraulic Pressure coal powder,charcoal powder,iron powder into ball,pillow,etc

3.Coal Charcoal Extruder

Extruding coal powder,charcoal powder,iron powder into lump charcoal.

4.Shisha Tablet Press

Hydraulic Press coal powder,charcoal powder into Shisha tablet.

5.Carbonization Furnace

Carbonizing wood,charcoal,branches,coconut shell,bamboo,etc material into charcoal.

Raw Material

Can be waste wood,bamboo,rice husk,sawdust,corn stalk,straw etc.

Can be coal powder,charcoal powder,iron powder,coke, iron oxide skin

Carbonized charcoal,charcoal powder,wood ,coconut shell.

Sugarcane baggage, palm thread, or other agricultural waste.

Final Product

Round ball, oval ball, pillow, cubic ball shapes

Hollow,hexagonal briquette log,

Lump charcoal,charcoal bar,charcoal stick

Shisha tablet.Square pillow

FAQ

●What is the voltage/phase for the machines?

We normally make it 220V/50Hz/Single Phase or 380V/50Hz/Three Phases. But it can be made according to clients' demand, like 110V/60Hz/Single Phase, 400V/50Hz/Three Phases etc.

●Will you make packaging before delivery, and what kind of packing box you will use?

For LCL cargo, we pack machines in export standard plywood boxes, no vermin, germs etc. help get better protection while transporting machines. For whole container cargo, sometimes no pack.

●How long is the guarantee for your machines?

We promise guarantee as one year for non-human damage factor.

●Do you supply spare part for machines?

If you want to change some parts after long time using, can contact us, we keep whole life spare parts supply.

●What's the payment terms?

We accept T/T, L/C, Western Union, MoneyGramm, trade assurance.

●For machines delivery by sea,what document will you supply for customs clearance?

Usually we supply Bill of Lading(Telex Released), Packing List and Invoice freely. If you need original document, we can send by express. And can supply other documents as customers demand, like CE, CO etc.

Hot Tags: charcoal carbonization plant, China, manufacturers, factory, cheap, low price, made in China