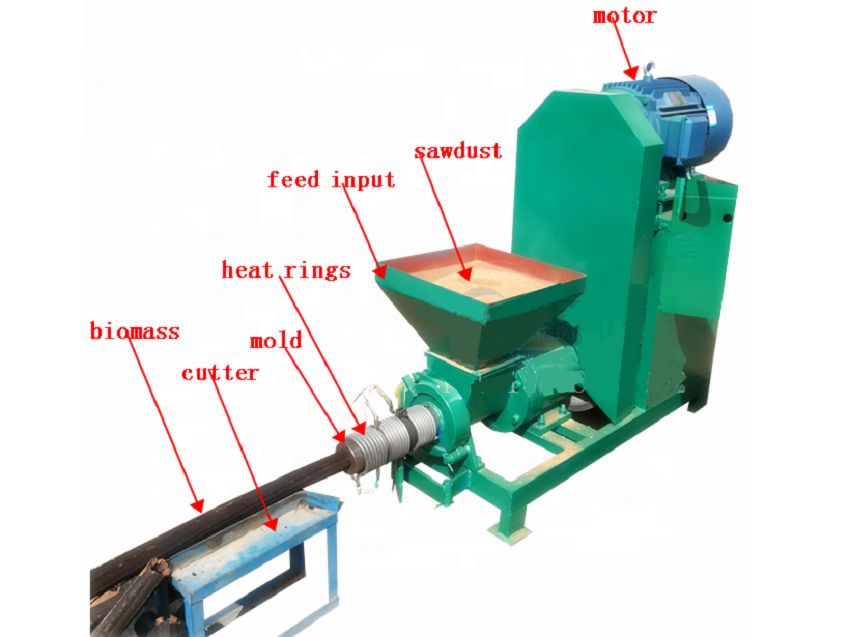

Wood briquette press also called biomass briquette machine and sawdust briquette machine, is used to convert sawdust into charcoal stick as biofuels ,used to heat boiler, fireplace, etc for warm in house.

Raw Materials

Agro-forestry wastes and biomass wastes, such as sawdust, crop straw, wood branches, rice hull, bamboo sawdust, peanut shell, coconut shell, sunflower shell, funeral dregs, cotton stalks, corn stalks, sesame straw, corncob and so on. The raw materials diameter should be below 3mm, and the moisture should be 8%-10%.

Working Principle is using screw propeller's high pressure and heating ring's high temperature, compress and extrude loose biomass into high density and small volume wood briquettes.

Features

●Screw propeller adopts precision casting, special wear-resisting material life for more than ten times higher than that of traditional thruster.

●Forming sleeve adopts special formula alloy precision casting, life can be up to 3 month;

●This cutting-edge technology not only makes the cost is greatly reduced, but also saves manpower.

●Finished wood briquettes are hollow quadrangular, hexagonal or cylindrical

●50-80 mm diameter rod shape, with 15-20 mm hole in it.

●Can used as fuel, boiler heating, cooking, and other field.

●Especially after carbonized, not only it has long burning time, but also smokeless, smelless, clean.

●Widely used in barbecue market.

Data Parameter

Model | Motor Powder | Voltage | Diameter | Capacity | Machine size/m | Weight |

BC-50 | 11kw | 380 or customized | 50mm | 140-200kg/h | 1.75*0.65*1.45m | 360 kg |

BC-80 | 15kw | 50mm | 180-230kg/h | 1.75*0.65*1.5m | 650 kg | |

BC-85 | 18.5kw | 80mm | 300-370kg/h | 1.87*0.66*1.6m | 900 kg |

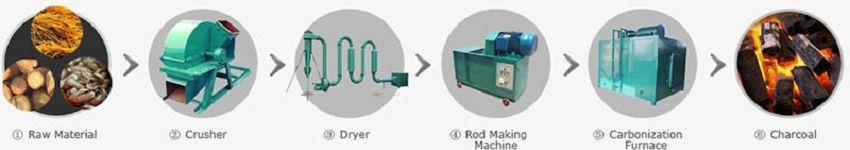

Complete production line

Raw materials----Crusher----Conveyor----Dryer----Conveyor----Biomass briquette machine----Carbonization furnace

Spare Parts

●The Inner Former can be used for 1-2 years.The former is made from a whole steel bar through a water jet cutting system so that the internal surface is smooth. Therefore, it’ll be easier to form and save energy. This is why the finished produces such as sawdust briquettes are smooth.

●We adopted three heating rings which are made from thick copper wires and are ceramic inside.

●Our wood briquette press machine adopts a durable material (high hardness alloy steel) to make the shaft. We use a different process then what is normally used to make the screw shaft. The screw shaft is manufactured with a milling machine which guarantees that the distance between every screw is the same, and the angle of every screw is the same.

FAQ

How is the quality of your products?

Our products are manufactured strictly according to national and international standard,and we take a test on every grinder before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed:

If products’ quality don’t accord to description as we give or the promise before you place order,we promise 100% refund.

How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”, if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

Welcome to visit our factory!

We will provide you our best equipments at the reasonable price to meet your requirements.

Hot Tags: wood briquette press, China, manufacturers, factory, cheap, low price, made in China