The most popular type of small pellet mill for sale is electric pellet mill.

Because of its relatively small capacity, usually the small pellet mills are used for home, small farm or small plants and workshops. The pellets made by the mill can be used for home heating, cooking, horse bedding, cat litter, and so on.

Performance Features

●Transmission gears made of High quality alloy steel,surface adopts carburizing and quenching treatment,precision machining by grinding,smooth transmission,low noise,large carrying capacity,low temperature rise,long life etc.

●Spindle with a heavy thrust bearing,support axial force,long life span.

●Roller and flat die wear peace deal,both side can use the flat die ,long service life.

●Pellet machine uses large diameter roller,big yield,pelletizing rate is high,uniform high strength pellets.

●All bearings are sealed structure that effectively prevent dust,improve the working bearings,environment,extending bearing lift..

●Highest grade tool steel die and rollers that are designed to fit YOUR PRODUCT.

●Full consultation at NO Charge at YOUR FACILITY.

●Low wear of roller,dies and bearings.

●Do not need to add binder.

●Pellet diameter from 6-12mm for user select.

●Easier to clean than pellet machine with ring die.

●Small and lightweight,available for homemade or farm pellet production.

●If you need support on selection of Pellet Machine,contact us.

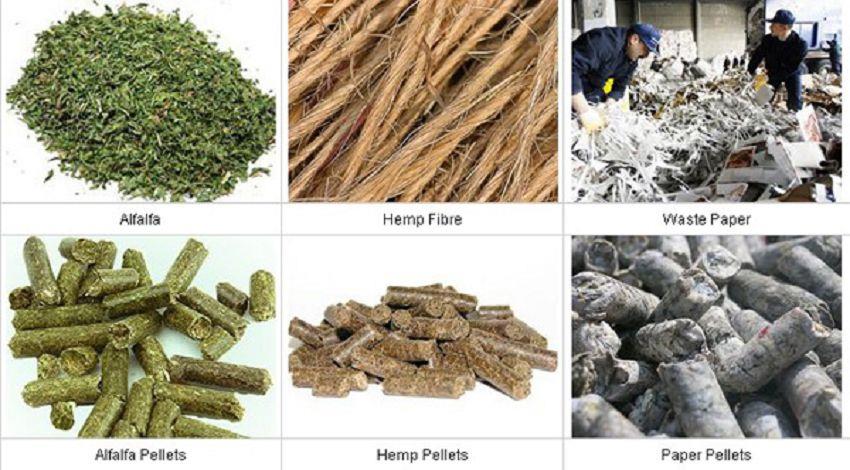

Raw Materials

For feed stuff use:

The compressed piece is suitable to be used as fuels and feedstuff of animals, such as horse, sheep, deer, pig, chicken, etc. Such machines are suitable for farms, and organic herbal medicine and chemical industry etc.

For wood pellets use:

This series flat die pellet presses can be used for producing wood pellets. Wood pellets are made of all kinds of wood sawdust and wood waste particle.

For biomass pellets use

Biomass pellets are made of peanut sheller, corn stalk and other biomass materials. Crushed agriculture waste including corn stalks, cotton stalks, wheat straw, rice husk, corn cob, groundnut shell,etc.

Technical Parameter

|

Type |

Power |

Capacity(kg/h) |

Dimension(mm) |

Weight(kg) |

|

PL-120 |

8HP |

60-100 |

730*320*670 |

135 |

|

PL-120B |

3KW |

60-100 |

750*310*620 |

100 |

|

PL-150 |

8HP |

100-200 |

760*430*710 |

150 |

|

PL-150B |

4KW |

150-220 |

770*340*680 |

115 |

|

PL-200 |

15HP |

220-350 |

1180*560*1020 |

360 |

|

PL-200B |

7.5KW |

200-300 |

1000*430*950 |

210 |

|

PL-230 |

11KW |

300-400 |

1150*500*970 |

320 |

|

PL-260 |

15KW |

400-600 |

1200*500*1030 |

370 |

|

PL-300 |

22KW |

600-800 |

1320*530*1070 |

480 |

Buying Guide

If you are looking for pellet machine ,want build your own pellet plant ,you can tell us below request:

1. What’s your raw material is ?

2. Raw material size mm,

3. Moisture content %

4. Final pellet diameter mm

5. Required capacity per hour?

6. Power required Motor,Diesel engine ,or PTO drive ?

7. Local voltage V/HZ

8. Whether need cooling and packing machine .

Upon we get your exactly request, we propose our plan with offer in short time.

Our Service

Pre-sales service:

Be a good consultant and assistant to customers, to ensure our customer's investment rewarded with great profit.

1. Enough details about the materials shall be learned, sometimes a test is needed for some materials.

2. Equipment of right model is selected for customers.

3. Customized products and processing flow sheet can be designed and developed to meet customer's special needs,

4. Engineer could be sent to observe customer's working site to come up with an optimized solution accordingly.

On-sales service:

Every customer is respected and convenience and reliability will be provided. We are devoted to helping you to benefit as much as possible.

1. Inspection is a must before delivering of the goods.

2. Assistance to make a construction plan by supplying all drawings and data needed.

3. Most favorable scheme for you with the guaranteed quality.

4. Timely communication to make sure improvement of project and your requirement met.

After-sales service:

1. Installation, adjustment, and testing of equipment is available.

2. Train of technicians and workers at site is promised.

3. Service engineers will not leave until ensuring the whole line running well after the installation & adjustment is finished.

4. If any failure or question about the machines or the processing line, contact us and we are available at any time.

Hot Tags: small pellet mill, China, manufacturers, factory, cheap, low price, made in China