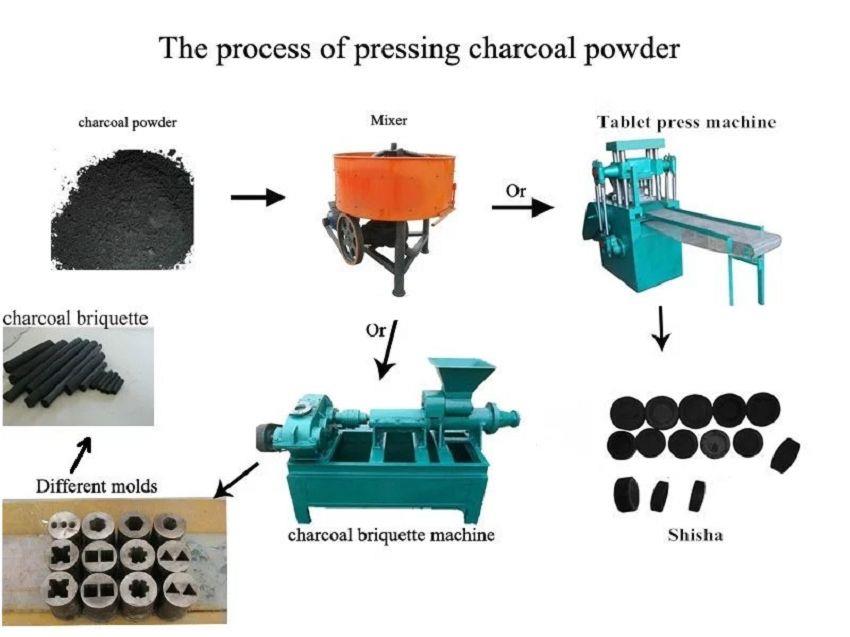

Charcoal extruder is also called carbon powder briquette machine, carbon powder extruder, which is a charcoal briquette forming machine whose raw material is firstly carbonized.

The biomass materials including sawdust, wood shavings, rice husk, peanut shell, bamboo shavings, etc are firstly processed in the carbonization furnace for 8 to 12 hours. After they are fully carbonized , the carbon powder will be sent into briquette machine to form into different shape charcoal briquettes. Charcoal briquette can be used as industrial carbon, home heating carbon, BBQ charcoal, etc.

Features

●This machine is to make coal and charcoal powder into sticks.

●This is the first step to make silver charcoal.

●The shape of the sticks can be made by customers requirements.

●The product made by this machine is no pollution and smoke. It is the most suitable machine for you.

●The machine can do shisha charcoal /sliver charcoal.

●It is suitable for charcoal powder, coconut shell charcoal powder, rice husk charcoal powder,charcoal dust, coal powder.

●For the material, the size should be less than 5 mm adding material, the coal moisture is 12% -14%.

●The shape and size of stick can be made as requires, like round, hexagon, cinquefoil or others,in the stick center, it can with hole or not.

●For the length, it has the auto-cutter.

Data Parameter

Model | Capacity | Roating speed | Power | Model size | Dimension(m) | Weight |

ET-140 | 2-3(t/h) | 46-60(r/min) | 11KW | 30-40mm | 1.4*0.9*0.6 | 1.5t |

ET-180 | 3-4(t/h) | 38-50(r/min) | 22KW | 30-60mm | 1.6*1.1*1.3 | 2.4t |

ET-210 | 4-5(t/h) | 30-40(r/min) | 30-37KW | 30-80mm | 1.9*1.4*1.45 | 3.5t |

ET-300 | 6-8(t/h) | 40-50(r/min) | 40-50KW | 30-100mm | 2.5*1.6*1.65 | 6t |

Our Services

Technical service

(1) Design for production line flow and equipment layout freely according to the site.

(2) Supply the foundation drawing of equipment.

(3) Supply the technical parameters of peripheral equipment.

(4) During the operation, we can offer the technology service freely if the user needs to adjust the layout and application.

(5) During the operation, we only collect the cost if the user willing to upgrade the equipment when we have the advantage technology.

After-sales service

(1) During the installation and commissioning, we shall send our technician to the site for guiding the installation and commissioning.

(2) During the installation and commissioning, we offer training service

(3) The buyer should pay the cost such as travel ling, lodging and eating and so on, and pay the service fee USD100/day/person.

(4) The quality assurance date is one year after commissioning.

(5) If the equipment appear the failure because of improper handling of user, we are in charge of maintenance, and collect the appropriate cost.

(6) We offer the components with favorable price, perdurable maintenance. After quality assurance date, if the equipments need to be repaired, we only collect the cost price.

FAQ

1. What's your payment term?

T/T30% as deposit, the rest 70% paid before shipment.

2. How many shapes does your machine can manufacture?

We can do round, cubic, hexagon, rectangular shape and triangle shape,etc.

3. Can i make different shapes with just one machine?

Yes, you can do different shape just by changing the mold.

4. How bout the density of the final products.

The final product is with high density and good appearance.

Hot Tags: charcoal stick extruder, China, manufacturers, factory, cheap, low price, made in China