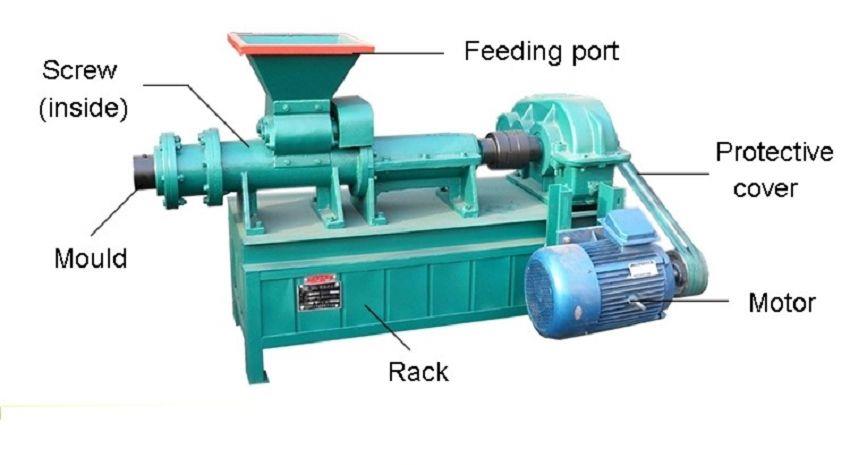

Coal sticks extruder machine is to make coal and charcoal powder into sticks.

The shapes can be various, such as finger shape,cubic shape, bar, hexagon,etc.which with High density,high hardness,stable shape,good performance,long burning time,convenient to store and transport .

Application

●This charcoal dust extruder is mostly used to make coal and charcoal powder into sticks. As the first step to make silver shisha(hookah) charcoal.

●The shape of the sticks can be designed depends on customers' requirements.

●The product made by this machine is no pollution and smoke. It is the most suitable machine for charcoal stick making.

●Adopt oil-immersed alloy structure, shaft, molding drum key components such as the use of special wear-resistant materials formula, precision casting, durable; Shaft, inside of cooperation between the gun barrel, compactness, wear-resisting degree have soared. New system of rods machine has the advantages of high output, low consumption, compact and durable.

Parameters

|

Model |

Capacity |

Roating speed |

Power |

Model size |

Dimension(m) |

Weight |

|

ET-140 |

2-3(t/h) |

46-60(r/min) |

11KW |

30-40mm |

1.4*0.9*0.6 |

1.5t |

|

ET-180 |

3-4(t/h) |

38-50(r/min) |

22KW |

30-60mm |

1.6*1.1*1.3 |

2.4t |

|

ET-210 |

4-5(t/h) |

30-40(r/min) |

30-37KW |

30-80mm |

1.9*1.4*1.45 |

3.5t |

|

ET-300 |

6-8(t/h) |

40-50(r/min) |

40-50KW |

30-100mm |

2.5*1.6*1.65 |

6t |

Operation

●The raw materials shouldn’t begin to be put into the machine before the White Coal Sticks Extruder running normally.

●The raw materials are not allowed to be left in the machine. Suppose the machine is stopped while during operation, the residual materials should be cleared immediately, and then the White Coal Sticks Extruder machine can be started again.

●The raw materials should be put into the machine uniformly. It's better to use feeding equipments together with White Coal Sticks Extruder

●The bearing part should be applied with butter regularly.

●Every bolt should be checked regularly to avoid flexibility.

●The bearing should be changed in time if it is damaged to avoid ruining other parts.

●While the machine is running, if there were abnormal noise, or the temperature was too high, or the motor current was too high, or other unappreciated cases, the extrude coal briquette machine should be stopped immediately.

●The V-belt should be removed while examining and repairing the machine for your safety.

Our Services

●Technical services

1. Designing production line and equipments layout according to your specific workshop.

2. Supplying drawings of equipments you’ve purchased.

3. Supplying technical parameters of peripheral equipments.

4. Offering technical service freely on request for adjusting the layout in your workshop.

5. Updating your equipments on request if necessary.

●After-sales services

6. During the installation and commissioning of the extrude charcoal briquette machine, we will send our technician to your site for guiding the installation and we will also offer training service for your party if requested.

7. If anything goes wrong with the extrude charcoal briquette machine because of improper handling, we’ll take care of the maintenance if requested, and material and labor costs will be charged at cost price.

8. We’ll offer spare parts for the extrude charcoal briquette machine with favorable price and perdurable maintenance. After the warranty expires, only material and labor costs will be charged if the equipments need to be repaired.

Company Profile

●Who we are

Established in 2004 , Anyang Ainuok Machinery is a professional extrude charcoal briquette machine manufacturer based in Henan Province. Every year, we exported hundreds of extrude charcoal briquette machine to French , Egypt, and Zimbabwe etc.

●What we do

We are specialized in manufacturing and exporting different models of extrude charcoal briquette machine, carbonization equipment and many other related coal machinery products.

●Why us

We use stringent quality control measures to ensure the reliability of our products. Our products including extrude charcoal briquette machine have gained CE and ISO 9001 certificate guarantee. With sound business credit, rich experiences, excellent after-sales services and modern manufacturing facilities, we’ll cooperate with and serve you better.Certificates

FAQ

Q: What is the raw material ?

A: Our extrude charcoal briquette machine suit raw material :coal powder ,charcoal power ,coke powder

Q: What is the capacity per hour ?

A: Capacity of Our extrude charcoal briquette machine from 1-10t/h

Q: How long is the warranty of the extrude charcoal briquette machine

A: Every set of How long extrude charcoal briquette machine can have a full year warranty. Malfunctions which are caused by the machine and its quality will be on our responsible. Other malfunctions which are caused by operation mistakes, man-made problems etc will be on our clients’ responsible.

Q: Where is your factory? How can I get there?

A: We are located in Zhengzhou, Henan Province, and the nearby airport is ZHCC. We can pick you up from the airport if needed.

Hot Tags: coal sticks extruder, China, manufacturers, factory, cheap, low price, made in China