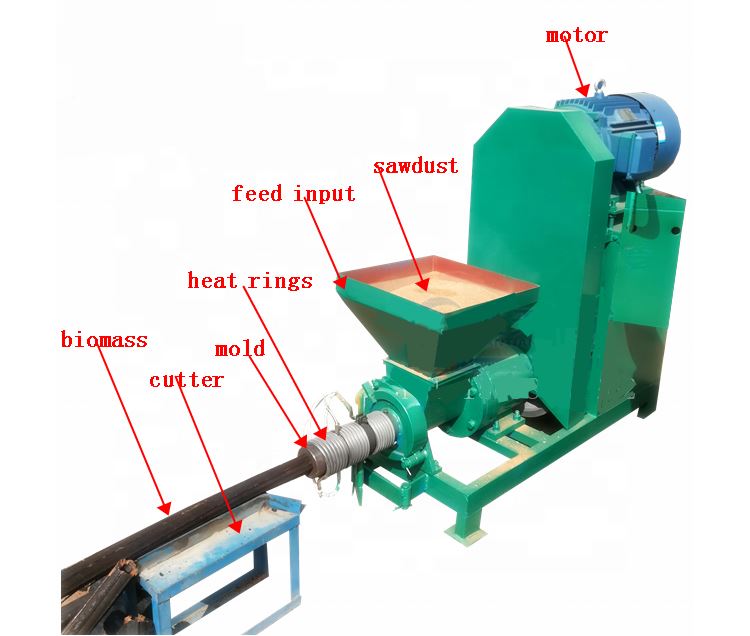

The straw briquetting machine is mainly used for processing waste such as straw, straw, peanut shell, corn cob and other crop straws, and can also be used for processing special equipment such as branches, bark and sawdust.

The straw briquetting machine can compress crop straw or crushed waste with a cut length (or soft silk) of 50 mm or less into a rod-shaped solid particle biofuel with a cross-sectional size of 30-40 mm and a length of 10-100 mm, and a compact block. After molding, the particles have large specific gravity and small volume, which are convenient for storage and transportation. It is a high-quality solid fuel with a calorific value of 3200-4500 kcal. It has the characteristics of flammable, low ash and low cost. It can replace fuel such as firewood and raw coal. It is widely used in heating, life stoves, boilers, biomass power plants, etc.

The straw or forage to be pressed is cut or crepe, the length of which is less than 50 mm, and the water content is controlled within the range of 10 to 25%. The material is fed into the feed port through the feeding conveyor, and the roller is driven by the spindle to drive the pressure roller. Rotating, and through the rotation of the pressure roller, the material is forced to extrude from the mold hole and fall from the discharge port, after cooling back (water content can not exceed 14%), bagging and packaging.

The die form of the straw briquetting machine is flat ring mold, and its structural features: First, the motor drives the reducer to drive the spindle to rotate, and then drives the pressure roller through the main shaft to rotate, the structure is simple and convenient to maintain; secondly, between the pressure roller and the mold The radial gap adjustment is convenient, which can ensure the most appropriate gap between the two pressure rollers and the mold; the third is to add an upper and lower electric heating ring, which can heat the ring mold, which is beneficial to material forming.