Sawdust briquette press machine is used to turn wood sawdust powder, palm shell powder, rice husk powder,biomass powder, leaves, shell, etc. into wood briquettes and BBQ charcoal briquettes. According to customer's requirements, we can provide you different kinds sawdust briquette press machines.

Feature

●The Sawdust briquette machine is use sawdust,crop straw,wood branches,coconut shell,cotton stalks,sesame straw,sugarcane waste, rice hulls, peanut shells,

●Bamboo crumbs and such materials to make fuel briquette under high temperature and pressure.

●These raw materials are crushed first, and then compressed into formed fuel products with high density and high calorific through machine pressing and heating(used sawdust briquette machine).

●The Sawdust briquette machine is not required any binder and chemical product .

●The raw material density is generally about 130kg/m3, and the density of formed charcoal bar is 1100- 1400kg/m3.

●The charcoal bar size is one over ten of the original,but its combustibility has been improved greatly.

●These charcoal bars can replace coals for producing and living, and the thermal efficiency is enhanced by 30%-40%.

|

Model |

BC-50 |

BC-80 |

|

Diameter |

50mm |

80mm |

|

Capacity |

200-250 kg/h |

250-300kg/h |

|

Power |

18.5kw |

22kw |

|

Weight |

550 kg |

700kg |

|

Out size |

1800*600*1600mm |

1800*700*1600mm |

|

Moisture |

5%-12% |

5%-12% |

Finished Product

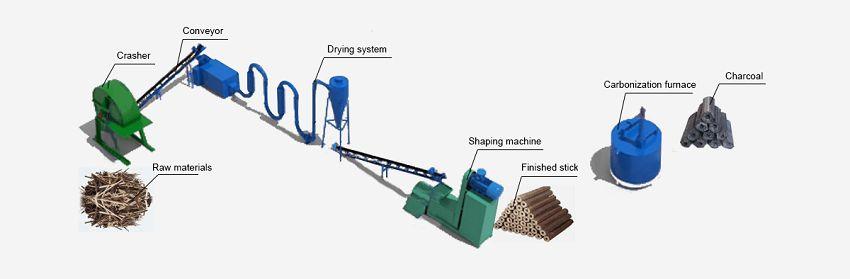

Complete Charcoal Process line

The process for producing charcoal briquette as follow:

1. Crush the raw material into small pieces (diameter is about 3-5mm)

2. Dry the material by machine or dried it in the sun , till the moisture is less than 12%

3. Put the material into feed let of briquette machine

4. Produce the briquette stick from biomass material without any additive

5. Carbonized the briquette stick(biomass briquette machine)

Picture Explanation

Raw material---Wood Crusher---Air flow dryer---charcoal briquette machine---Carbonization Furnace--- Wood Charcoal

Spare Parts

Long Life of Screw Shaft

Our machine adopts a durable material (high hardness alloy steel) to make the shaft. We use a different process then what is normally used to make the screw shaft. The screw shaft is manufactured with a milling machine which guarantees that the distance between every screw is the same, and the angle of every screw is the same.

Long Life of Inner Former

The Inner Former can be used for 1-2 years.The former is made from a whole steel bar through a water jet cutting system so that the inner face is smooth. Therefore, it’ll be easier to form and save energy. This is why the finished produces such as sawdust briquettes are smooth. It consists of two parts and you need to change only the key part when it is worn.

Heating section

We adopted two heat collars which are made from thick copper wires and are ceramic inside. An attractive feature on the forming hopper is that we added a movable plate on the bottom. It has two functions, one is you can clean it easily. The other is that you can discharge the inputted material when it is jammed.

Lubricating System

The gear box is equipped with lubricating system. Moreover, to oil the gear box properly, our briquette machine is designed with an exhaust function which can help maintain consistent air pressure.

Auto Cutting System

It’s a simple piece of equipment composed of two steel plates. (Please see the picture), and briquettes can be automatically cut in uniformed lengths.

FAQ

How is the quality of your products?

Our products are manufactured strictly according to national and international standard,and we take a test on every grinder before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed:

If products’ quality don’t accord to description as we give or the promise before you place order,we promise 100% refund.

How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”, if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

Welcome to visit our factory!

We will provide you our best equipments at the reasonable price to meet your requirements.

Professional Sales

We cooperate with our customers to any necessary documents.

We are sales team,with all technical support from engineer team.

Before sending the machines, we will test and adjust.

Operating video & instruction will be sent to clients, to help them better use the machines.

Any problems occur while using, professional advice will be given by us.

After-sales Service

We respect your any feedback after receiving the goods.

We provide 12 months warranty after goods arrive.

We promise all spare parts available in lifetime use.

We handle your complain within 48 hours.

Hot Tags: sawdust briquette machine, China, manufacturers, factory, cheap, low price, made in China