Hoist Airflow Type Charcoal Carbonization Furnace Not only it has best carbonization effect and shortest carbonization time,It can collect wood tar oil and exhaust gas.After processed, this gas can used recycling fuel. it is no any open fire, totally dry distillation.

|  |

| Hoist Carbonization Machine | QHL-2 Carbonization Machine |

●Raw Materials

This machine can change wood log, wood briquette, coconut shell and bamboo Palm shells etc directly into final charcoal

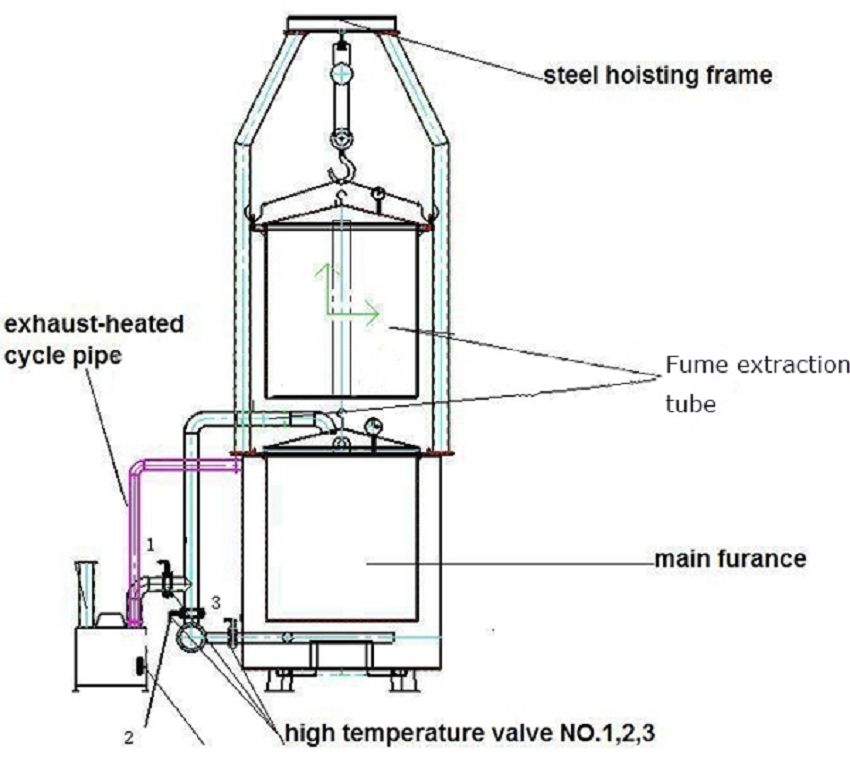

●Carbonization Machine Parts

One whole set machine = one outer stove+ three inner stoves+ electric hoist + clean system.

●Daily productivity Whole sets Machine

2-3T/24hrs for dry wood with moisture less than 8% or wood briquettes.

Different moisture of the raw materials, the daily productivity will be different & try to make sure the

wood log to be similar size, or the carbonize effect will be effected & make sure moisture no more

than 50%

●Basic Work Principle

Main Features : continuous carbonization +Smoke recycle burning + Self Purifying

1)Put fuel into the heating part and light it until temperature reach about 400 degree(there is a temperature indicator on the machine ) ,then put the inner pot full with wood log etc into the outer stove to be carbonization wood charcoal horizontal continuous carbonization furnace

2)During carbonization process, the inside charcoal briquette will produce flammable air,this air will from top to the bottom to be burning again, then it continuous to do this circulation process,so there is no pollution at all during the whole process

3)After one pot wood finish carbonize, then lift it out to let another pot into the outer stove

4)By doing this repeatably,the machine can work without stop

●Carbonization Machine size & weight of Whole sets machine

Outer stove diameter 1890mm /outer stove

Inner pot diameter 1500mm/1450mm/1400mm

Loading Size 2.1*2.2*2.1meters. Weight 3000kg

Note : 1*40GP container can hold 4 whole sets machine

●Carbonization Machine Materials

Mn High temperature resistant plate 6-12mm according different part

●Fuel consume

20-30 kg firewood or 15 kg liquefied gas per time

Only pre-heating need consume fuel, pre heating time is about 80-100minutes

●Carbonization time

Wood logs ( 8-10hours), wood briquettes (8hours), coconut shell (6hours)

●About cooling

After carbonizing, we need to take the inside pot out, let it cool by natural way, the longer cooling time the better for charcoal quality

Model Name | Capacity | Mainly Included Parts | Shipping |

QHL-1 | 2-3ton/24hour | 1outer stove+3 inner pot | LCL |

QHL-2 | 5-6ton/24hour | 2outer stove+6 inner pot | FCL 1*20GP |

QHL-3 | 7-9ton/24hour | 3outer stove+9 inner pot | FCL 1*40GP |

QHL-4 | 10-12ton/24hour | 4outer stove+12inner pot | FCL 1*40GP |

Packaging Details

●If the equipments have been finished, it needs 5 days for us to prepare for the delivery .

●If the customer want to make some changes to the finished products, needs 10-15 days to prepare for the delivery.

●If you want a new set of equipments, we need 20-25 days.

●Sea Port:Qingdao, Shanghai,Tianjin port, etc

Our Service

●For our Wood Carbonization Stove, we offer details explanation for customer in each step

●Welcome customer come to our factory - to check any of our Charcoal Carbonization Stove

●After sign contract,we give customer video showing for the manufacturing process each day

●After customer buy the charcoal making machine,we sent engineer install abroad & training worker

●Warrant time 12month - for all of our Wood Carbonization Stove, briquetting machine etc

●For all our Wood Carbonization Stove , offer free technical support any time .

●Will inform previous buyer according new products - according new charcoal machines

●Help any customer if anything need we do in China

Hot Tags: hoist carbonization machine, China, manufacturers, factory, cheap, low price, made in China